The Core Principle: Compartmentalisation via Automatic Duct Isolation

Why HVAC ducts act as fire highways—and how fire dampers interrupt them

The ductwork in heating, ventilation and air conditioning systems actually acts as highways for fire and poisonous smoke to move freely between different parts of a building during emergencies. This rapid spread not only damages structures faster but puts people inside at greater danger too. That's where fire dampers come into play. These devices automatically shut off at key points in the duct system when they detect heat, forming essential firebreaks that stop flames from escaping their starting area. By doing so, they maintain what fire safety experts call compartmentalization, which is basically keeping fires contained. The dampers work by cutting off both oxygen flow and heat movement through the building's ventilation system, making them an important part of modern fire protection strategies.

Fail-safe thermal activation: Fusible links, heat sensors, and the critical 165°F threshold

Most modern systems actually use two main ways to activate them reliably. First there are those fusible links made from special metal alloys that melt at specific temps. When things get hot enough, these links break apart and let go of those spring loaded dampers inside. The second method relies on electronic heat sensors instead. These sensors kick in when they detect temperatures staying above around 165 degrees Fahrenheit for some time. That's the standard set through UL 555S tests we all know about. What makes this setup so good is it still works even if there's no electricity running. Field tests done recently by NFPA back this up pretty well too. Their 2023 research found almost 99 out of every 100 systems activated properly during actual fires last year.

Fire Damper Operation Modes: Static vs Dynamic Response Under Real Fire Conditions

Static dampers: Passive closure for non-pressurised systems

Fire dampers that stay put until needed work quietly in building systems meant to stop air movement when flames break out. These devices depend entirely on heat signals such as those old fashioned fusible links that melt around 165 degrees Fahrenheit or newer electronic sensors picking up rising temperatures. When triggered, the damper blades snap shut thanks to springs inside them, sealing off ducts running through walls and floors. These are really important spots because they block smoke spread between different parts of a building once normal airflow stops. Best suited for places where pressure isn't too high, static fire dampers need proper HVAC system shutdown procedures so they can close properly without fighting against strong air currents.

Dynamic dampers: Pressure-resistant closure during active airflow and smoke movement

Fire dampers designed for dynamic operation work against continuous airflow in essential spaces such as hospital intensive care units and laboratory environments where ventilation must keep running during emergency situations. The engineering team typically strengthens the damper blades and frames so they can handle pressure differences beyond 4 inches water gauge. According to UL 555 standards, these devices need to shut down when air moves through them faster than 2,000 feet per minute, which shows how well they fight back against smoke movement caused by inertia forces. Most installations include an extra safety buffer that keeps everything working properly even if conditions push past the normal operating range by around 400 feet per minute.

Validated Performance: Fire Ratings, Testing Standards, and Real-World Efficacy

UL 555 and EN 1366-2: What 90-minute and 180-minute fire resistance ratings actually mean

Fire resistance ratings basically tell us how long building components can hold up against intense heat in lab tests. Standards like UL 555 in the US and EN 1366-2 across Europe put fire dampers through their paces at temperatures over 1800 degrees Fahrenheit. They check for three main things when testing these dampers: whether flames get through, if the structure collapses, and if too much heat passes through. When a damper gets a 90 minute rating, that means it stayed intact for about an hour and a half inside those furnace tests. This kind of rating would contain a full blown office fire situation pretty well. The higher 180 minute ratings matter a lot more in places like tall buildings or hospitals where people need extra time to evacuate safely. All these numbers aren't just theoretical either. Labs actually test them independently to make sure they meet these baseline requirements before anyone installs them in real structures.

NFPA evidence: Correlation between certified fire damper installation and reduced fire fatalities

When buildings follow fire damper standards, people actually stand a better chance of surviving fires. A look at data from over 450 commercial fires between 2019 and 2023 shows that places with properly certified dampers had around 68% fewer deaths caused by smoke inhalation. There are basically two reasons why this happens. First off, these dampers cut off oxygen to the flames which can slow down how fast a fire spreads by as much as 40%, according to some technical reports from NFPA in 2024. Second, they stop smoke from traveling through ventilation systems where most fire deaths occur. Buildings that have their dampers checked by independent experts tend to give occupants about 11 extra minutes to get out safely. That extra time makes all the difference when it comes to saving lives during emergencies.

Critical Components and System Integration for Reliable Fire Damper Function

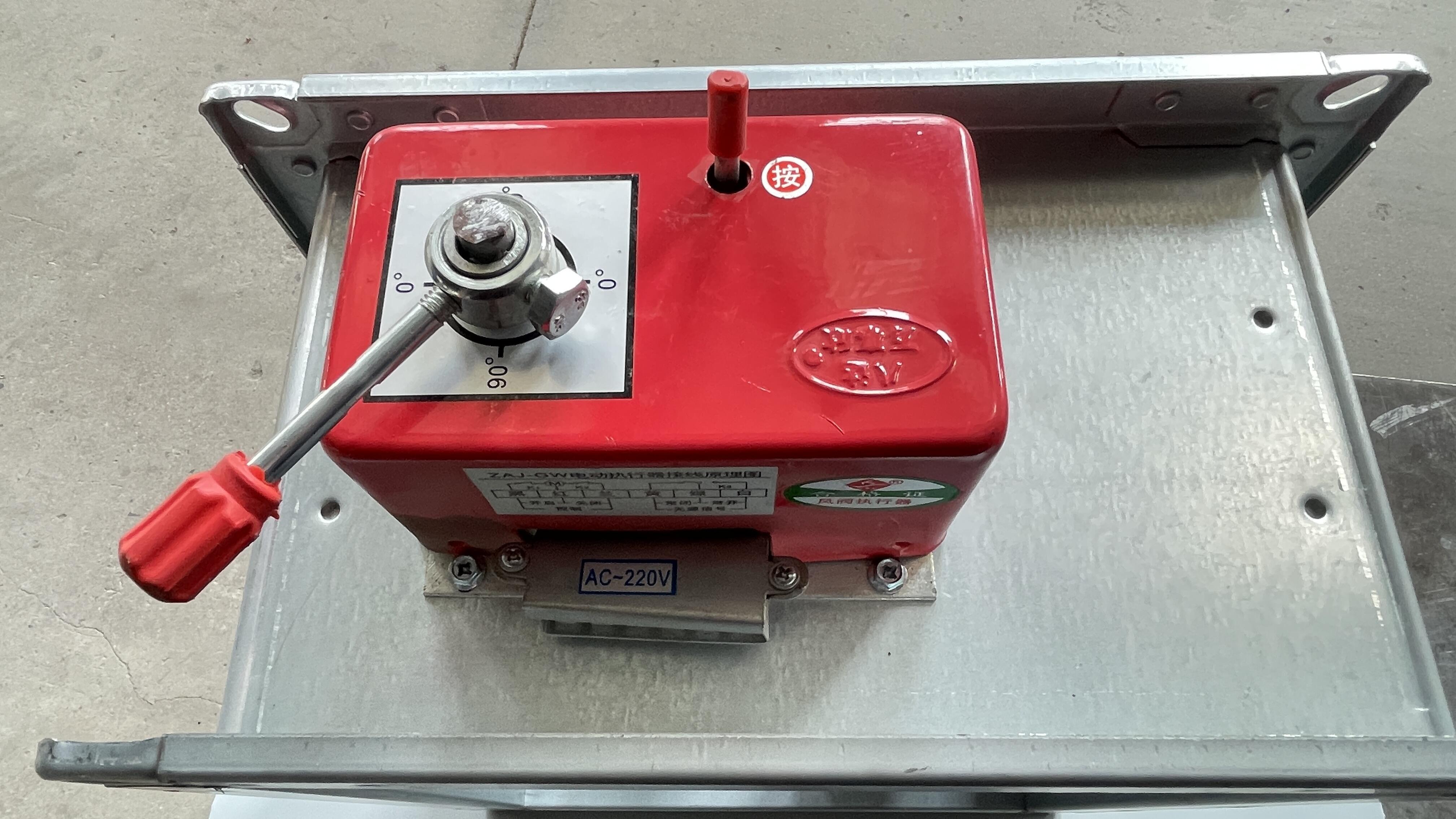

Frame, blade, seal, and actuator—how interdependent design ensures fail-safe closure

The frame holds the fire damper securely inside the duct system and keeps everything aligned even when temperatures change. The curved blades are loaded with springs so they can deploy quickly when needed. These blades lock together tightly when closed, stopping both air and flames from passing through. The special rubber seals get bigger as heat rises past around 165 degrees Fahrenheit (about 74 Celsius), sealing up tiny spaces between the blades and frame to stop smoke from getting through. The actuator connects all these parts together. It works whether the fusible links melt or there's an electronic signal sent. When activated, it moves the blades into position while the seal adjusts for any small manufacturing differences. Because these components rely on each other mechanically, there's built-in safety. If one part fails, the rest will still work against fire spread until someone can fix or replace the faulty component manually.

Synchronisation with fire alarms, sprinklers, and building management systems

Fire containment works best when it connects properly with building safety systems. When smoke detectors go off, dampers need to shut down fast, usually within seconds. The newer fire systems have these addressable relays that talk to alarm panels, so they know exactly which area needs attention. That means the right dampers close near where the smoke was detected first. Getting everything to shut down at once before the sprinklers kick in stops dangerous smoke from spreading through ventilation ducts or messing up fire suppression efforts. Most modern buildings now have Building Management Systems (BMS) that watch all this from a central location. These systems run automatic tests every month using those dry contact signals we mentioned earlier. Fire safety experts have found something interesting too. Buildings with integrated systems like this cut down on human mistakes by around two thirds compared to older standalone setups. Makes sense really, since fewer people need to manually check things during emergencies.

| Component | Integration Purpose | Failure Risk Mitigation |

|---|---|---|

| Fire Alarm | Immediate damper closure upon detection | Dual-signal verification protocols |

| Sprinkler System | Pre-activation damper sealing | Pressure-independent blade design |

| BMS | Remote diagnostics & automated testing | Continuous health monitoring alerts |

This multi-system coordination transforms fire dampers from passive devices into responsive life-safety assets that adapt to evolving fire scenarios while automatically logging performance data for compliance reports.

FAQs

What is the main function of fire dampers?

Fire dampers are designed to interrupt the spread of fire and smoke through HVAC duct systems. They automatically close when they detect heat, providing critical firebreaks that contain the fire in one area of a building.

How are fire dampers activated?

Fire dampers can be activated through fusible links that melt at high temperatures or electronic heat sensors that detect sustained heat above a certain threshold—typically around 165 degrees Fahrenheit.

What is the difference between static and dynamic fire dampers?

Static fire dampers operate passively by shutting off airflow in systems where pressure is not high, whereas dynamic dampers are designed to resist closure pressure and continue functioning in environments with active airflow, such as in hospitals or labs.

Why are fire resistance ratings important?

Fire resistance ratings indicate how long components like fire dampers can endure intense heat during lab tests. Higher ratings ensure better performance in real fire scenarios, allowing more time for evacuation.

How do fire dampers contribute to fire safety?

By cutting off oxygen supply and preventing smoke from spreading through ventilation systems, fire dampers significantly enhance fire containment and provide additional time for safe evacuations.

Are building management systems essential for fire damper operation?

Yes, integrating fire dampers with building management systems enables remote diagnostics, automated testing, and efficient coordination with other fire safety systems like alarms and sprinklers, reducing chances of human errors during emergencies.